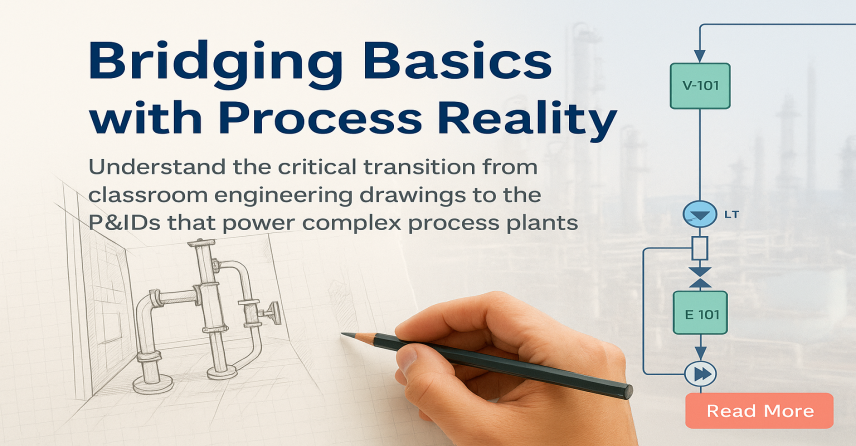

Introduction: Why Engineering Drawing Still Matters in Modern Process Plants

For most chemical engineering students, engineering drawing is an early-semester obstacle—largely a matter of projections, isometric drawings, and line work. But step into the realm of design consultancy or a live plant environment, and you'll find that this subject quietly determines how plants are constructed, reconfigured, and safely operated.

The single most important real-world application? Piping and Instrumentation Diagrams (P&IDs).

These are not simply "sketches"—they are the central nervous system of plant design. P&IDs are mastered through the visualization of chemical processes--and that fluency begins with engineering drawing.

Theory Summary: What Engineering Drawing Will Teach You

In engineering drawing class, you will usually learn:

Orthographic Projections – 2D representations of 3D objects

Isometric Views – Flat 3D images to see equipment arrangement

Sectional Drawings – Cut-away views to reveal inner details

Line Types and Symbols – Distinction between object lines, hidden lines, and centre lines

Dimensioning and Scaling – Sizing components correctly

Standard Conventions – application of templates, borders, and symbols for valves, fittings, and instruments

These skills have a direct correlation to the creation and reading of P&IDs in industry.

Real-World Correlation: How P&IDs Are Constructed on Engineering Drawing Principles

Let's dissect this with a real-world example: planning a distillation system in a specialty chemicals facility.

During the design stage, a chemical process engineer and a piping designer work together on the P&ID:

•Equipment profiles (such as columns, reboilers, condensers) are located utilizing orthographic concepts.

•Piping lines are sketched using isometric thinking to prevent interferences.

•Standard drawing symbols are employed in adding instruments, valves, and safety devices—just like in class.

•Specific line types, weights, and conventions for labelling are used by every line on a P&ID, whether it's utility, process, or drain.

•Section views or exploded diagrams are applied when several nozzles or internal parts (such as trays or coils) need to be depicted.

Without an engineering drawing foundation, working out or producing a P&ID is unclear and error-ridden.

Software Tools That Bridge Theory and Practice

In college, you may work with graph paper and drawing tools. In the real world, CAD and intelligent diagramming tools take over:

- AutoCAD – Used for basic 2D schematics and layouts

- SmartPlant P&ID – Industry-standard tool with intelligent tagging and equipment database integration

- Aveva Diagrams – Enables collaborative work on large-scale plant diagrams with live updates

These tools still follow the same drawing principles—they just scale them to industrial levels.

Why It Matters: Safety, Operations, and Compliance Depend on It

A single incorrect symbol or misrouted line on a P&ID can lead to:

- Safety hazards (e.g., bypassing a pressure relief valve)

- Process inefficiencies (e.g., incorrect control loop logic)

- Failed audits and regulatory violations (e.g., undocumented drains or vents)

Because P&IDs are used by process engineers, safety teams, control engineers, maintenance crews, and plant operators, clarity and precision—rooted in engineering drawing—are essential.

Takeaways for Students and Early Professionals

✅ Engineering drawing isn’t a “basic” subject—it’s the blueprint of your future work.

✅ Every good P&ID starts with strong drawing fundamentals: projection, symmetry, symbols, and attention to detail.

✅ Learn drawing software early—but understand the why behind each line and shape.

✅ In plant design, P&IDs speak louder than words. Your drawing knowledge lets you read and write that language fluently.

Want to Learn P&IDs the Industry Way?

Viggyantech’s live design modules and weekend courses walk you through real P&ID development—from symbol libraries to interlock logic. Start mastering the skills that matter in real jobs. Know the real concepts behind developing P&IDs from scratch.